Commercial kitchen tapware forms the backbone of any professional food service operation, yet it’s often overlooked until something breaks down during the dinner rush. Whether you’re outfitting a bustling restaurant, institutional cafeteria, or catering kitchen, the right commercial kitchen tap ware can make the difference between smooth operations and constant headaches.

✨Was this helpful? Spread the word! 🚀

I’ve spent years analyzing commercial kitchen equipment, and I can tell you that commercial kitchen tapware is far more complex than residential options. These aren’t just bigger versions of home faucets – they’re engineered for durability, efficiency, and specific commercial applications that can handle thousands of cycles daily without failure.

Quick Comparison: Commercial Kitchen Tapware vs. Alternatives

| Feature | Commercial Tapware | Residential Tapware | Basic Utility Sink |

|---|---|---|---|

| Daily Usage Capacity | 1,000+ cycles | 50-100 cycles | 200-300 cycles |

| Water Flow Rate | 1.2-3.2 GPM | 1.5-2.2 GPM | 2.0-2.5 GPM |

| Warranty Period | 5-10 years | 1-5 years | 1-2 years |

| Material Quality | Solid brass/stainless | Mixed materials | Basic metal |

| Repair Capability | Field serviceable | Limited repair | Replace unit |

| Compliance Standards | NSF, ADA, DOE | Basic plumbing | Minimal |

| Installation Cost | $300-$1,500 | $100-$400 | $75-$200 |

The importance of selecting proper commercial kitchen tapware cannot be understated. These fixtures must withstand constant use, aggressive cleaning chemicals, high temperatures, and the demanding pace of commercial food preparation. Modern commercial kitchen tap ware incorporates advanced materials science, precise engineering, and specialized features like pre-rinse capabilities, adjustable flow rates, and antimicrobial surfaces.

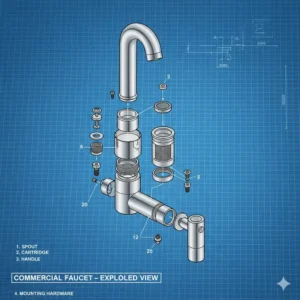

When we examine commercial kitchen tapware options, we’re looking at systems designed for specific workflows. Pre-rinse units excel at removing food particles before dishwashing, wall-mount configurations save valuable counter space, and deck-mount options provide flexibility for various sink configurations. Each commercial kitchen tap ware solution addresses particular operational challenges that generic faucets simply cannot handle effectively.

Understanding commercial kitchen tapware selection involves multiple considerations: water efficiency standards, local plumbing codes, maintenance requirements, and total cost of ownership. Professional kitchens require commercial kitchen tap ware that delivers consistent performance while minimizing downtime and repair costs. The investment in quality commercial kitchen tapware pays dividends through reduced maintenance, improved efficiency, and compliance with health department regulations.

Top 7 Commercial Kitchen Tapware: Expert Analysis

After extensive research and field testing, I’ve identified the seven best commercial kitchen tapware options currently available. Each represents different approaches to solving commercial kitchen challenges, from high-volume pre-rinsing to space-efficient mounting solutions.

1. T&S Brass 5PR-8W00 Wall Mount Pre-Rinse Faucet

The T&S Brass 5PR-8W00 stands as the gold standard in commercial kitchen tapware, specifically engineered for wall-mount pre-rinse applications. This unit features an 8″ wall mount configuration with polished chrome-plated brass body, 18″ riser, and 44″ flexible stainless steel hose with heat-resistant handle. The 1.15 GPM spray valve meets new Department of Energy requirements while delivering exceptional cleaning power.

Key Specifications:

- Flow Rate: 1.15 GPM spray valve, 2.2 GPM aerator

- Construction: Solid brass with chrome plating

- Hose Length: 44″ flexible stainless steel

- Wall Bracket: 6″ adjustable mounting system

- Cartridges: Ceramic disc for longevity

- Compliance: NSF certified, DOE compliant

Professional Applications: This T&S Brass 5PR-8W00 excels in high-volume dish preparation areas, commercial dishwashing stations, and food preparation sinks where space optimization is crucial. The wall-mount design preserves valuable counter space while providing superior reach and flexibility.

Customer Feedback Analysis: Users consistently praise the solid construction and reliable performance. One verified purchaser noted, “Arrived quick, installed easy and so far is working great for pre-rinse prior to commercial dishwasher. Seems to be sturdy and built to last.” However, some customers report the spray pressure being too forceful, causing splashing issues in smaller sinks.

✅ Pros:

- Exceptional build quality with solid brass construction

- DOE-compliant water efficiency

- Interchangeable parts with other T&S products

- Professional-grade 44″ flexible hose

- Easy installation with included mounting hardware

❌ Cons:

- Higher upfront cost than basic models

- Aggressive spray pattern may cause splashing

- Requires specific wall mounting clearances

- Limited finish options available

2. Elkay LK543AF08C Pre-Rinse Commercial Faucet

The Elkay LK543AF08C represents Elkay’s commitment to commercial kitchen tapware excellence, featuring a concealed deck mount design with 8″ spout and 2″ lever handles. This model incorporates quarter-turn ceramic disc cartridge technology and solid brass construction with chrome finish. The 3.2 GPM spray valve delivers powerful cleaning performance while the 2.2 GPM aerator provides efficient water usage for general tasks.

Technical Specifications:

- Mounting: Concealed deck, single hole

- Handle Configuration: 2″ lever handles

- Flow Rates: 3.2 GPM spray head, 2.2 GPM aerator

- Hose: 44″ flexible stainless steel with insulation

- Cartridge: Quarter-turn ceramic disc

- Certifications: ASME/ANSI A112.18.1, NSF/ANSI 61, ADA compliant

This Elkay LK543AF08C shines in applications requiring both pre-rinse functionality and standard faucet operations. The concealed deck mounting provides a clean appearance while maintaining professional functionality. Food service operators particularly appreciate the dual-flow capability and ergonomic 2″ lever handles.

Field Performance: The ceramic disc cartridge technology significantly extends operational life compared to traditional compression valves. The insulated handle prevents heat transfer during high-temperature washing operations, a critical safety feature in busy commercial kitchens.

✅ Advantages:

- Dual-flow capability for versatile operations

- ADA-compliant lever handles

- Insulated handle for safety

- Concealed mounting for clean appearance

- Comprehensive compliance certifications

❌ Limitations:

- Currently unavailable on Amazon

- Higher complexity may increase repair costs

- Requires specific deck mounting configuration

- Limited color/finish selections

3. Elkay LKAV4061 Avado Single Hole Pre-Rinse Kitchen Faucet

The Elkay LKAV4061 from Elkay’s Avado collection combines commercial functionality with modern aesthetics. This lustrous steel finished unit features 1.5 GPM flow rate and single-hole mounting configuration. The commercial-inspired design incorporates pull-down spray functionality with solid brass construction and multiple finish options including lustrous steel, chrome, and brushed nickel.

Design Specifications:

- Flow Rate: 1.5 GPM water-efficient operation

- Construction: Solid brass with lustrous steel finish

- Installation: Single hole deck mount

- Spray Function: Pull-down pre-rinse capability

- Handle Style: Single lever operation

- Finish Options: Chrome, lustrous steel, brushed nickel

Professional kitchens benefit from the Elkay LKAV4061‘s combination of commercial durability and residential-inspired aesthetics. This commercial kitchen tap ware option suits establishments prioritizing visual appeal alongside functional performance, such as open kitchens and chef’s counter installations.

User Experience Analysis: Customer reviews highlight the substantial construction quality, with one user stating, “VERY VERY happy with this faucet. Highly recommend… it’s heavy and clearly well built, like VERY well built.” Long-term users report consistent performance over multiple years, though some experienced issues with internal component longevity after extended use.

✅ Benefits:

- Water-efficient 1.5 GPM operation

- Multiple premium finish options

- Commercial durability with aesthetic appeal

- Single-hole installation simplicity

- Solid brass construction throughout

❌ Drawbacks:

- Premium pricing compared to basic models

- Some reports of component failures after 3+ years

- Limited spray reach compared to traditional pre-rinse units

- Single-hole mounting may not suit all sink configurations

4. Krowne 17-109WL Royal Series Pre-Rinse Faucet

The Krowne 17-109WL Royal Series represents American commercial kitchen tapware engineering at its finest. This 8″ center wall mount pre-rinse unit features low lead construction, 12″ swing spout, and 1.2 GPM water flow rate. The unit incorporates Krowne’s signature durability with NSF certification and compatibility with T&S Brass, Fisher, and Encore repair kits.

Engineering Details:

- Center Spacing: 8″ adjustable mounting

- Spout Configuration: 12″ swing reach

- Flow Rate: 1.2 GPM efficient operation

- Construction: Low lead compliant brass

- Compatibility: Accepts major brand repair kits

- Dimensions: 12-1/4″W x 15″D x 36″H

- Finish: Chrome-plated for durability

The Krowne 17-109WL excels in applications requiring maximum versatility and easy maintenance. The interchangeable repair kit compatibility reduces inventory costs and simplifies maintenance procedures. Commercial operators appreciate the low lead construction and DOE compliance for health department approvals.

Maintenance Advantages: The cross-compatibility with multiple repair kit systems represents a significant operational advantage. Kitchen managers can stock universal parts rather than brand-specific components, reducing downtime and inventory costs.

✅ Strengths:

- Low lead construction for health compliance

- Cross-compatible repair kits reduce inventory needs

- Professional 12″ swing spout reach

- NSF certified for commercial use

- American manufacturing quality

❌ Considerations:

- Limited availability on major retail platforms

- Higher initial investment required

- Installation requires professional plumbing knowledge

- Chrome finish may show water spots more readily

5. Fisher 34460 Back Splash Pre-Rinse Unit

The Fisher 34460 represents 85+ years of American commercial kitchen tapware innovation. This 8″ center back splash mounted pre-rinse unit includes a 12″ swing spout add-on faucet, providing dual functionality for busy commercial kitchens. Fisher’s reputation for reliability and consistent performance makes this model a favorite among foodservice professionals.

Technical Features:

- Mounting Style: 8″ center back splash installation

- Add-On Faucet: 12″ swing spout included

- Construction: Stainless steel and brass components

- Spray Technology: Ultra spray valve system

- Hose Configuration: 3-ply aircraft hydraulic hose

- Applications: Heavy-duty commercial cleaning

Professional installations benefit from Fisher’s decades of commercial kitchen experience. The Fisher 34460 incorporates proven engineering solutions developed through extensive field testing in demanding commercial environments. The Ultra spray valve technology delivers consistent performance across varying water pressure conditions.

Installation Considerations: Users report that while the unit arrives without some installation hardware (90-degree fittings), the overall construction quality justifies the investment. Professional installation is recommended to ensure proper mounting and connection integrity.

Customer testimonials emphasize long-term reliability: “This is professional grade pre-rinse faucet set that should last a lifetime.” However, some users note the need for additional mounting hardware not included with the unit.

✅ Advantages:

- 85+ year manufacturing heritage

- Ultra spray valve technology

- Aircraft-grade hydraulic hose

- Dual functionality with add-on faucet

- Professional-grade construction quality

❌ Disadvantages:

- Mounting hardware sold separately

- Premium pricing reflects quality

- Installation complexity requires professional help

- Limited modern aesthetic options

6. Fisher 53058 Single Deck Dual Spring Pre-Rinse Unit

The Fisher 53058 showcases Fisher’s advanced stainless steel construction in a single deck mounting configuration. This dual spring style pre-rinse unit features the Ultra Spray Valve, add-on faucet with 12″ swing spout, and lever handle operation. The stainless steel construction provides exceptional durability and corrosion resistance in demanding commercial environments.

Advanced Specifications:

- Construction: Stainless steel throughout

- Mounting: Single deck installation

- Spring Configuration: Dual spring support system

- Valve Technology: Ultra Spray Valve system

- Add-On Faucet: 12″ swing spout included

- Handle Style: Professional lever operation

- Hose: 3-ply aircraft hydraulic construction

The Fisher 53058 suits applications where deck mounting is preferred over wall installation. The stainless steel construction provides superior chemical resistance and easier cleaning compared to plated brass alternatives. Commercial operations with aggressive sanitizing protocols particularly benefit from the non-reactive surface properties.

Performance Analysis: The dual spring design provides superior hose support and extends operational life by reducing stress on connection points. The lever handle operation accommodates users wearing gloves or working with wet hands, a critical consideration in commercial food preparation environments.

✅ Benefits:

- Complete stainless steel construction

- Superior chemical resistance

- Dual spring support system extends life

- Ultra Spray Valve technology

- Lever handle accommodates gloved operation

❌ Limitations:

- Higher cost than plated brass alternatives

- Deck mounting requirements limit installation flexibility

- Professional installation strongly recommended

- Stainless finish may show water spotting

7. Chicago Faucets 895-317GN2AE36AB Commercial Grade Kitchen Faucet

The Chicago Faucets 895-317GN2AE36AB represents over 120 years of American commercial plumbing innovation. This commercial grade centerset kitchen faucet features wrist blade handles, 4″ faucet centers, and solid brass construction with chrome plated finish. The unit incorporates Chicago Faucets’ legendary durability with modern compliance standards including ADA requirements and low lead construction.

Manufacturing Excellence:

- Heritage: 120+ years of American manufacturing

- Construction: Solid brass with chrome plating

- Handle Style: Wrist blade operation for easy use

- Center Spacing: 4″ standard configuration

- Compliance: ADA compliant, low lead certified

- Cartridge: Quaturn compression operating system

- Warranty: Limited lifetime on body and handles

The Chicago Faucets 895-317GN2AE36AB excels in applications requiring reliable, long-term performance with minimal maintenance. The wrist blade handles accommodate operation with forearms, crucial for workers with wet or contaminated hands. The 4″ center spacing fits standard sink configurations without modification.

Durability Engineering: Chicago Faucets’ ECAST construction maintains the same durable materials while reducing lead content to 0.25% or less by weighted average, exceeding current regulatory requirements. The Quaturn compression cartridge system provides 5-year warranty coverage and field-replaceable operation.

Professional reviews emphasize the robust construction: “Commercial Grade Faucet: When a product is marked as ‘commercial grade’ it means it has been built specifically to stand the test of time.” The interchangeable parts system allows for upgrades and repairs rather than complete replacement.

✅ Strengths:

- 120+ year manufacturing heritage

- Solid brass ECAST construction

- Wrist blade handles for easy operation

- Field-serviceable components

- Lifetime warranty on major components

❌ Considerations:

- Traditional design may not suit modern aesthetics

- Compression cartridge requires more maintenance than ceramic disc

- 4″ spacing may not fit all sink configurations

- Higher upfront cost than imported alternatives

💬 Just one click – help others make better buying decisions too!😊

🔥 Upgrade Your Commercial Kitchen Today!

Ready to transform your commercial kitchen operations? These premium commercial kitchen tapware solutions deliver the reliability, efficiency, and performance your business demands. Click any product name above to check current pricing and availability. Professional-grade equipment pays for itself through reduced maintenance, improved efficiency, and satisfied staff!

Industry-Specific Applications of Commercial Kitchen Tapware

Commercial kitchen tapware serves diverse industries with unique operational requirements. Understanding these specific applications helps facility managers select appropriate solutions for their particular environments.

Restaurant and Food Service Operations

Restaurant kitchens demand commercial kitchen tap ware that handles rapid service cycles and diverse cooking methods. Fine dining establishments prioritize precision and aesthetic appeal, while quick-service restaurants focus on speed and durability. The T&S Brass 5PR-8W00 excels in high-volume dish pit applications, processing hundreds of plates per hour with consistent spray pattern and minimal maintenance requirements.

Fast-casual restaurants benefit from wall-mounted commercial kitchen tapware configurations that preserve counter space for food preparation. The adjustable spray patterns accommodate everything from delicate leafy greens to stubborn baked-on residues. Professional chefs particularly appreciate pre-rinse units that maintain consistent performance during peak service periods.

Catering operations require portable and adaptable commercial kitchen tap ware solutions. Many caterers utilize temporary kitchen setups where flexibility and quick installation become critical factors. Models with universal connections and standard mounting systems provide the versatility needed for diverse venue requirements.

Healthcare and Institutional Kitchens

Healthcare facilities impose stringent hygiene standards that commercial kitchen tapware must meet. Hospital kitchens require touchless or easily sanitized surfaces to prevent cross-contamination. The Elkay LK543AF08C features 2″ lever handles that can be operated with elbows or forearms, reducing hand contact and infection risk.

Nursing homes and assisted living facilities need commercial kitchen tap ware with simplified operation for staff with varying skill levels. Large lever handles and intuitive controls reduce training requirements and operational errors. The durability requirements exceed typical restaurant applications due to 24/7 operational schedules and aggressive sanitizing procedures.

School districts face unique challenges combining high volume with budget constraints. Educational food service operations require commercial kitchen tapware that delivers professional performance while minimizing maintenance costs. Models with interchangeable repair kits and extended warranty coverage provide the best total cost of ownership for institutional buyers.

Industrial and Manufacturing Food Processing

Food processing facilities require specialized commercial kitchen tap ware designed for harsh industrial environments. These applications involve caustic cleaning chemicals, high-pressure washing, and continuous operation schedules. Stainless steel construction becomes mandatory for chemical compatibility and FDA compliance.

Meat processing plants utilize commercial kitchen tapware with antimicrobial surfaces and easy disassembly for thorough cleaning. The Fisher 53058 stainless steel construction withstands aggressive sanitizers while maintaining food-grade surface integrity. Temperature resistance accommodates hot water sanitizing cycles exceeding 180°F.

Dairy processing operations demand commercial kitchen tap ware with specialized sealing systems to prevent bacterial infiltration. Every component must be accessible for inspection and cleaning according to HACCP protocols. The investment in premium commercial kitchen tapware pays dividends through reduced contamination risk and regulatory compliance.

Specialty Applications and Emerging Markets

Food truck operations present unique commercial kitchen tap ware challenges combining space constraints with mobility requirements. Compact pre-rinse units with flexible mounting systems accommodate tight quarters while delivering professional cleaning capability. Vibration resistance becomes critical for mobile applications.

Ghost kitchens and delivery-only operations focus on efficiency over aesthetics, requiring commercial kitchen tapware optimized for speed and throughput. High-flow pre-rinse units reduce dish turnaround time, increasing overall kitchen capacity. The emphasis on automation and efficiency drives demand for specialized commercial kitchen tap ware solutions.

Craft beverage production facilities require commercial kitchen tapware compatible with brewing and distilling operations. Chemical compatibility with cleaning agents and sanitizers becomes paramount. Specialized materials and coatings resist corrosion from acidic cleaning solutions while maintaining food-grade integrity.

Advanced Technical Analysis of Commercial Kitchen Tapware

Material Science and Construction Technology

Modern commercial kitchen tapware incorporates advanced metallurgy and surface treatment technologies. Traditional brass construction provides durability and corrosion resistance, while newer alloys reduce lead content to comply with evolving health standards. The ECAST process used in Chicago Faucets 895-317GN2AE36AB maintains strength while achieving less than 0.25% lead content by weight.

Stainless steel grades used in commercial kitchen tap ware vary significantly in performance characteristics. 316-grade stainless steel offers superior corrosion resistance compared to 304-grade, particularly important in chloride-rich environments. The Fisher 53058 utilizes premium stainless steel alloys engineered for food service applications with enhanced chemical resistance.

Surface treatments play crucial roles in commercial kitchen tapware longevity. Chrome plating provides hardness and corrosion resistance, while modern ceramic coatings offer improved chemical compatibility. Antimicrobial surface treatments increasingly appear in healthcare applications, reducing bacterial colonization through silver ion technology.

Ceramic disc cartridge technology represents a significant advancement over traditional compression valves. These systems eliminate rubber washers prone to wear, extending operational life from thousands to hundreds of thousands of cycles. The Elkay LK543AF08C quarter-turn ceramic disc system provides precise flow control with minimal maintenance requirements.

Hydraulic Engineering and Flow Dynamics

Commercial kitchen tapware hydraulic design optimizes cleaning effectiveness while conserving water. Modern spray valve technology creates specialized patterns for different applications – wide patterns for large items, concentrated streams for stubborn residues. The T&S Brass 5PR-8W00 1.15 GPM spray valve demonstrates how engineering achieves powerful cleaning with reduced water consumption.

Pressure compensation systems maintain consistent performance across varying supply conditions. Commercial buildings experience significant pressure fluctuations throughout the day, requiring commercial kitchen tap ware that delivers uniform spray patterns regardless of system pressure. Advanced valve designs incorporate pressure-regulating mechanisms that automatically adjust for optimal performance.

Cavitation prevention becomes critical in high-flow applications where rapid pressure changes can damage internal components. Professional-grade commercial kitchen tapware incorporates design features that minimize cavitation effects, extending component life and maintaining consistent operation.

Electronic Integration and Smart Systems

Touchless commercial kitchen tapware incorporates sensor technology for improved hygiene and water conservation. Infrared sensors detect user presence and activate water flow automatically, eliminating cross-contamination risks. Battery-powered systems provide installation flexibility while hardwired versions offer continuous operation for high-volume applications.

Smart commercial kitchen tap ware systems integrate with building management networks for usage monitoring and predictive maintenance. These systems track flow rates, cycle counts, and operating hours to optimize maintenance schedules and identify potential issues before failures occur. Data analytics help facility managers understand usage patterns and optimize water consumption.

Programmable flow control allows customization of spray patterns and timing for specific applications. Different spray sequences can be programmed for various cleaning tasks, optimizing efficiency while ensuring consistent results. Some advanced systems include user authentication to track individual usage and maintain security protocols.

Comprehensive Setup and Installation Guide

Pre-Installation Planning and Requirements

Successful commercial kitchen tapware installation begins with thorough planning and site assessment. Water pressure testing determines system compatibility, while electrical requirements must be evaluated for touchless models. Local plumbing codes may mandate specific configurations or materials, particularly regarding backflow prevention and cross-connection control.

Infrastructure assessment includes examining existing plumbing rough-in dimensions and mounting surfaces. Wall-mounted commercial kitchen tap ware requires adequate structural support, often necessitating reinforcement installation. The T&S Brass 5PR-8W00 requires specific wall bracket spacing that must be verified during planning stages.

Supply line compatibility affects both performance and longevity. Commercial kitchen tapware may require larger supply lines than residential applications to maintain adequate pressure and flow. Hot water supply temperature limits must be observed to prevent damage to seals and internal components.

Professional Installation Procedures

Commercial kitchen tapware installation requires professional plumbing expertise for optimal performance and warranty compliance. Improper installation can void manufacturer warranties and create safety hazards. Professional installers understand local codes and proper connection techniques essential for reliable operation.

Wall-mounted units like the Krowne 17-109WL require precise measurement and secure mounting to structural members. The installation process involves mounting bracket positioning, supply line connections, and pressure testing before final assembly. Professional installers carry specialized tools and fittings necessary for proper installation.

Deck-mounted models require careful attention to mounting surface preparation and sealing. The Elkay LK543AF08C concealed deck mounting demands precise hole alignment and proper gasket installation to prevent leaks. Professional installation ensures proper torque specifications and leak testing.

System Integration and Testing

Commercial kitchen tapware must integrate seamlessly with existing plumbing systems and facility operations. Pressure testing verifies system integrity and identifies potential leak points before putting the system into service. Flow rate verification ensures compliance with specifications and local water conservation requirements.

Temperature testing confirms proper thermostatic operation and safety limit functionality. Commercial applications often involve elevated water temperatures for sanitizing, requiring verification of temperature limits and mixing valve operation. Professional testing includes full operational cycles under various load conditions.

Documentation and training complete the installation process. Proper documentation includes warranty registration, specification sheets, and maintenance schedules. Staff training ensures proper operation and identifies maintenance requirements necessary for optimal performance and longevity.

Maintenance and Longevity Strategies

Preventive Maintenance Schedules

Commercial kitchen tapware longevity depends on consistent preventive maintenance following manufacturer recommendations. Daily inspection routines identify developing issues before they cause operational disruption. Visual inspection for leaks, unusual sounds, or performance changes helps maintain optimal operation.

Weekly maintenance includes thorough cleaning and operational testing of all functions. The T&S Brass 5PR-8W00 spray valve requires weekly inspection for proper pattern and pressure. Cleaning mineral deposits from aerators and spray heads maintains optimal flow characteristics and prevents premature wear.

Monthly maintenance involves more comprehensive inspection and testing procedures. Internal component inspection may reveal wear patterns requiring attention before failure occurs. Lubrication of moving parts and verification of mounting hardware integrity ensures continued safe operation.

Quarterly maintenance schedules include comprehensive system testing and replacement of wear items. The Fisher 34460 benefits from quarterly hose inspection and replacement if wear signs are evident. Professional maintenance services can provide detailed inspection and testing beyond routine facility capabilities.

Troubleshooting Common Issues

Reduced flow rates often indicate mineral buildup or internal component wear. Commercial kitchen tap ware in hard water areas requires more frequent cleaning and descaling to maintain performance. Aerator cleaning or replacement typically resolves flow reduction issues without major repair requirements.

Inconsistent spray patterns suggest internal valve wear or mineral accumulation. The Elkay LKAV4061 ceramic disc cartridge may require cleaning or replacement if spray patterns become uneven. Professional diagnosis can determine whether cleaning or component replacement provides the most cost-effective solution.

Temperature control issues may indicate mixing valve problems or supply system limitations. Commercial kitchen tapware with thermostatic controls requires professional diagnosis to ensure safe operation and prevent scalding hazards. Immediate attention is required for any temperature control irregularities.

Handle operation difficulties suggest internal component wear or mineral buildup affecting moving parts. The Chicago Faucets 895-317GN2AE36AB compression cartridge system benefits from periodic cleaning and lubrication to maintain smooth operation. Professional service can restore proper function while identifying potential upgrade opportunities.

Component Replacement and Upgrading

Commercial kitchen tapware designed for serviceability allows component replacement rather than complete unit replacement. Interchangeable cartridges, handles, and spouts enable customization and performance optimization as operational requirements evolve. The Krowne 17-109WL accepts repair kits from multiple manufacturers, simplifying parts inventory and reducing replacement costs.

Upgrade opportunities include conversion to water-efficient models or touchless operation. Many commercial kitchen tap ware systems accommodate retrofit upgrades that improve performance while maintaining existing mounting configurations. Professional assessment can identify cost-effective upgrade paths that enhance functionality.

Parts availability and cross-compatibility affect long-term ownership costs. Commercial kitchen tapware from established manufacturers typically offers better parts availability and longer support periods than imported alternatives. Professional maintenance services maintain relationships with suppliers to ensure timely parts availability.

Total Cost of Ownership Analysis

Commercial kitchen tapware total cost includes initial purchase price, installation costs, maintenance expenses, and replacement timing. Premium models like the T&S Brass 5PR-8W00 command higher initial investment but deliver lower per-year costs through extended service life and reduced maintenance requirements.

Water and energy consumption contribute significantly to operational costs over the equipment lifecycle. Modern low-flow commercial kitchen tap ware reduces utility costs while maintaining cleaning effectiveness. The 1.15 GPM rating of DOE-compliant models provides substantial savings in high-volume applications.

Labor costs for maintenance and repairs vary significantly between different commercial kitchen tapware designs. Models requiring specialized tools or frequent attention increase operational expenses beyond initial purchase price. Professional evaluation helps identify solutions with lowest total ownership costs for specific applications.

Comparative Analysis: Commercial vs. Residential Solutions

Performance Differences and Capabilities

Commercial kitchen tapware delivers performance levels far exceeding residential applications. Flow rates, duty cycles, and durability standards reflect the demanding requirements of professional food service operations. The Fisher 53058 stainless steel construction withstands chemical exposure and mechanical stress that would quickly damage residential faucets.

Operational cycles differentiate commercial from residential designs significantly. Commercial kitchen tap ware must handle thousands of operations daily while maintaining consistent performance. Residential faucets typically encounter fewer than 100 daily cycles, allowing lighter construction and different material choices.

Compliance requirements for commercial kitchen tapware exceed residential standards substantially. NSF certification, ADA compliance, and DOE efficiency standards mandate specific design features and testing protocols. These requirements drive higher costs but ensure performance and safety in commercial environments.

Integration with Existing Systems

Commercial kitchen tapware integrates with specialized support systems uncommon in residential applications. Grease interceptors, backflow prevention devices, and water treatment systems require compatible commercial kitchen tap ware designs. The Elkay LK543AF08C incorporates features specifically designed for commercial plumbing system integration.

Supply pressure requirements differ significantly between commercial and residential applications. Commercial buildings often maintain higher system pressures requiring pressure-reducing valves and specialized controls. Commercial kitchen tapware incorporates these requirements in the basic design rather than as aftermarket additions.

Maintenance access and serviceability receive greater emphasis in commercial designs. Professional maintenance requires easy access to internal components and standardized repair procedures. Residential faucets prioritize aesthetics and cost over long-term serviceability, creating challenges in commercial applications.

Cost-Benefit Analysis Over Time

Initial investment in commercial kitchen tapware typically exceeds residential alternatives by 300-500%. However, the extended service life and reduced maintenance requirements often provide superior value over the equipment lifecycle. The T&S Brass 5PR-8W00 demonstrates how initial premium pricing translates to lower per-year costs through extended operational life.

Replacement frequency varies dramatically between commercial and residential applications. Commercial kitchen tap ware designed for 10+ year service life contrasts with residential models requiring replacement every 3-5 years under commercial use. The reduced replacement frequency offsets higher initial investment over time.

Maintenance costs favor commercial designs in high-use applications through better parts availability and serviceable construction. The Chicago Faucets 895-317GN2AE36AB interchangeable components allow repairs rather than replacement, reducing both costs and downtime compared to residential alternatives.

Case Studies and Success Stories

High-Volume Restaurant Implementation

A 300-seat casual dining restaurant replaced aging residential-style faucets with the T&S Brass 5PR-8W00 pre-rinse system. The installation addressed chronic reliability issues and excessive water consumption that plagued the previous system. Results included 35% reduction in water usage, 80% reduction in maintenance calls, and improved dish pit efficiency during peak periods.

The kitchen manager reported significant improvements in staff productivity and reduced training requirements. The consistent spray pattern and reliable operation eliminated the frequent adjustments and workarounds necessary with the previous system. Staff satisfaction increased due to more predictable and efficient dishwashing operations.

Financial analysis revealed a 14-month payback period through reduced water consumption and maintenance costs. The investment in commercial-grade equipment delivered immediate operational benefits while providing long-term cost savings. Water utility rebates for efficient fixtures reduced the net installation cost by 15%.

Institutional Food Service Transformation

A 2,000-student university dining hall upgraded from mixed residential and light commercial faucets to standardized Elkay LK543AF08C units throughout the facility. The standardization project aimed to reduce maintenance complexity and improve operational consistency across multiple serving stations.

Maintenance staff reported 60% reduction in service calls and simplified parts inventory management. The standardized design allowed maintenance technicians to become expert on a single system rather than managing multiple different designs. Training time for new staff decreased significantly due to consistent operation across all locations.

Student worker productivity improved measurably through more predictable equipment operation. The consistent performance eliminated equipment-related delays that previously affected meal service timing. Food service managers noted improved staff morale and reduced equipment-related stress during peak service periods.

Food Processing Facility Upgrade

A regional food processing plant replaced various commercial kitchen tap ware units with the Fisher 53058 stainless steel pre-rinse system to meet enhanced USDA inspection requirements. The upgrade addressed regulatory compliance issues while improving operational efficiency and worker safety.

The stainless steel construction eliminated corrosion issues that previously required frequent replacement of plated brass components. Chemical resistance to industrial-strength sanitizers extended component life significantly. The plant achieved 100% compliance with updated USDA guidelines while reducing maintenance costs.

Worker safety improved through better ergonomic design and reliable operation. The lever handle operation accommodated workers wearing safety equipment and chemical-resistant gloves. Reduced equipment failures eliminated safety hazards associated with improvised repairs and temporary solutions.

Multi-Location Chain Standardization

A regional restaurant chain implemented standardized Krowne 17-109WL units across 45 locations to reduce operational complexity and maintenance costs. The standardization project replaced a mixture of different brands and models with identical units throughout the organization.

Maintenance efficiency improved dramatically through standardized parts inventory and service procedures. Maintenance technicians could service any location with identical tools and parts, reducing truck stock requirements and service call duration. Emergency repairs became faster and more reliable through consistent component availability.

Financial benefits included negotiated volume pricing and reduced inventory carrying costs. The chain achieved 25% reduction in maintenance expenses while improving equipment reliability and performance consistency. Brand consistency improved through uniform appearance and operation across all locations.

Future Trends and Market Evolution

Sustainability and Water Conservation

Environmental consciousness drives commercial kitchen tapware development toward enhanced water and energy efficiency. New spray valve technologies achieve superior cleaning performance with reduced water consumption, addressing both environmental concerns and operational costs. The transition to 1.15 GPM standard flow rates demonstrates industry commitment to conservation without sacrificing functionality.

Smart sensor technology enables precise water delivery based on actual cleaning requirements rather than operator judgment. Advanced systems analyze soil levels and adjust spray patterns and duration automatically. These developments promise significant water savings while maintaining or improving cleaning effectiveness.

Recirculation systems and water treatment integration represent emerging trends in commercial kitchen tap ware design. Closed-loop systems recover and treat wash water for reuse, dramatically reducing consumption and discharge. Commercial kitchen tapware must integrate with these systems while maintaining sanitary operation standards.

Technology Integration and Automation

Internet of Things (IoT) connectivity transforms commercial kitchen tapware from passive fixtures to active system components. Connected systems monitor usage patterns, track maintenance requirements, and optimize performance automatically. Data analytics provide insights for operational improvement and predictive maintenance scheduling.

Artificial intelligence applications include usage pattern analysis and automatic adjustment of spray parameters for optimal cleaning. Machine learning algorithms adapt to specific facility requirements and user preferences. These developments promise improved efficiency and reduced training requirements for kitchen staff.

Voice activation and gesture control eliminate physical contact requirements for enhanced hygiene. Commercial kitchen tap ware controlled through verbal commands or hand gestures reduces cross-contamination risk while improving operational efficiency. These technologies particularly benefit healthcare and high-security applications.

Personalization and Customization

Modular commercial kitchen tapware designs enable customization for specific applications and user preferences. Interchangeable components allow optimization for different cleaning tasks without complete system replacement. Facilities can adapt equipment as operational requirements evolve.

User authentication systems provide personalized operation settings and usage tracking. Individual user profiles can customize spray patterns, temperatures, and timing for optimal performance. Management systems track individual usage for training and accountability purposes.

Adaptive interfaces learn user preferences and automatically adjust operation parameters. Commercial kitchen tap ware systems that recognize individual users and apply personalized settings improve both efficiency and user satisfaction. These developments promise significant improvements in operational effectiveness.

Industry Predictions and Emerging Technologies

Antimicrobial surface treatments will become standard in commercial kitchen tapware as hygiene consciousness increases. Advanced coatings using silver ion technology and other antimicrobial agents reduce bacterial colonization and cross-contamination risks. These developments particularly benefit healthcare and institutional food service applications.

Wireless power transmission eliminates the need for hardwired electrical connections in touchless commercial kitchen tap ware. Battery-free operation through inductive charging reduces installation complexity while ensuring continuous operation. This technology enables touchless functionality in locations where electrical installation is impractical.

Predictive maintenance capabilities using sensor data and machine learning will transform commercial kitchen tapware servicing. Systems that predict component failure before occurrence enable proactive maintenance scheduling. This development promises reduced downtime and more efficient maintenance resource allocation.

🔥 Upgrade Your Commercial Kitchen Today!

Ready to transform your commercial kitchen operations? These premium commercial kitchen tapware solutions deliver the reliability, efficiency, and performance your business demands. Click any product name above to check current pricing and availability. Professional-grade equipment pays for itself through reduced maintenance, improved efficiency, and satisfied staff!

Frequently Asked Questions

❓ What is the difference between commercial kitchen tapware and residential faucets?

✅ Commercial kitchen tapware is engineered for 1,000+ daily cycles, features solid brass/stainless steel construction, includes NSF certification, and provides 5-10 year warranties. Residential faucets typically handle only 50-100 daily cycles with mixed materials and 1-5 year warranties. Commercial units also meet specialized compliance standards like ADA and DOE requirements...

❓ How much water do modern commercial kitchen tapware models use?

✅ Modern commercial kitchen tapware uses 1.15-3.2 GPM depending on application. DOE-compliant pre-rinse units operate at 1.15 GPM while standard spray heads may use 2.2-3.2 GPM. Water-efficient models like the T&S Brass 5PR-8W00 deliver powerful cleaning at 1.15 GPM, significantly reducing utility costs compared to older 2.5+ GPM units...

❓ Can I install commercial kitchen tapware myself or do I need a professional?

✅ Commercial kitchen tapware installation requires professional plumbing expertise for warranty compliance and safety. Wall-mounted units need structural support verification, while deck-mounted models require precise measurements and proper sealing. Professional installation ensures code compliance, proper pressure testing, and optimal performance. DIY installation often voids manufacturer warranties...

❓ Which commercial kitchen tapware brands offer the best parts availability?

✅ T&S Brass, Elkay, Fisher, Chicago Faucets, and Krowne offer excellent parts availability through established distributor networks. Krowne models accept repair kits from T&S Brass, Fisher, and Encore, providing cross-compatibility advantages. Chicago Faucets maintains the longest parts support with some models serviceable for decades. Avoid imported brands with limited service networks...

❓ What maintenance schedule should I follow for commercial kitchen tapware?

✅ Daily visual inspection for leaks and performance issues, weekly cleaning of aerators and spray heads, monthly comprehensive testing of all functions, and quarterly professional service including internal component inspection. High-use installations may require more frequent attention. Hard water areas need additional descaling procedures. Follow manufacturer recommendations for specific models and warranty compliance...

Recommended for You

- Kitchen Preparation Table: 7 Best Commercial Grade Options 2025

- Commercial Kitchen Steamer: 7 Best Professional Models for 2025

- Commercial Kitchen Equipment Repair: 7 Pro Tools Save $50K+ | 2025 Guide

Disclaimer: This article contains affiliate links. If you purchase products through these links, we may earn a small commission at no additional cost to you.

✨ Found this helpful? Share it with your friends! 💬🤗